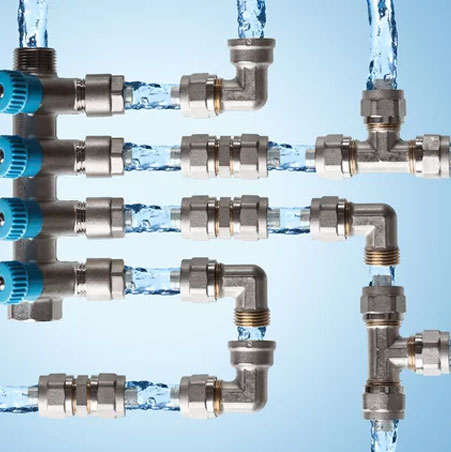

Ready Stock Of SS 316L Bulkhead Union, 316L SS Twin Ferrule Fittings, Stainless Steel 316L Female Elbow, Manufacturer of ASTM A182 TP316L Hydraulic Tube Fittings, SS 316L Male Connector Supplier in Mumbai.

Unifit Metal Alloys is a recognised exporter and stockist of SS 316L Tube Fittings, whichis highly resistant to a broad variety of atmospheric conditions as well as many corrosive media. Stainless Steel UNS S31603 Female Branch Tee Tube Fittings has long-term corrosion resistance, excellent impact resistance and bend ability adherence, excellent saline damage prevention, excellent bond strength with concrete, and so on. This alloy's balanced austenitic structure allows it to be seriously deep drawn without interim annealing. It is widely used in the production of drawn steel components such as sinks, hollowware, and saucepans. Because of the chromium content, it has great corrosion/oxidation protection. The fundamental iron and carbon composition of all steels is the same, but this steel also includes a good dose of chromium. This steel's composition is well-known for its corrosion resilience.

Stainless Steel 316L Female Connector, UNS S31603 Tube Fittings, DIN 1.4435 Ferrule Fittings, SS 316L Reducing Union, SS 316L Tube To Union, 316L Stainless Steel Single & Double Ferrule Tube Fittings, Stainless Steel 316L Union Elbow, SS 316L Back Ferrule Manufacturer In Mumbai, India.

The large quantities of nickel and chromium in austenitic Stainless Steel WNR 1.4404 Male Adapter Tube Fittings provide excellent corrosion protection as well as excellent mechanical qualities. It is also very susceptible to the thiosulfate anions produced by pyrite oxidation at room temperature. It can be easily braked or rolled into a number of components for use. When compared to the "standard" grade, it has a small but perceptible decrease in critical mechanical performance qualities. It serves many functions, many of which combine. It is the stainless steel family's most flexible and commonly used alloy.In operation, it is less prone to embrittlement and hypersensitivity.

316L Stainless Steel Female Adapter Tube Fittings outperform other metals in most conditions and have excellent strength at temperatures up to 2100 degrees Fahrenheit. They are extensively used in mildly carburizing environments, such as those found in petrochemical plants. It has exceptional high temperature strength, as well as resilience to creep deformation and environmental assault. It is resistant to suffixation and can be used in mildly carburizing atmospheres due to its high chromium and modest nickel concentration. It is used in coal gasified interior components, refractory anchor fasteners, lead pots, thermo wells, and other similar applications. It is also very ductile and wieldable, allowing it to be used in a broad range of uses.

Get a best quote for SS TP316L Tube Fittings, We Keep Bulk Stock of Stainless Steel 316L Tube To Union at our stockyard, contact us to request a quote.

Stainless Steel 316L Tube Fittings Specifications

| Specifications | ASTM A182, A276, A479 / ASME SA182, SA276, SA479 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |