Stainless Steel 304H Female Elbow, SS 304H Male Connector, Ready Stock Of SS 304H Bulkhead Union, Manufacturer of ASTM A182 TP304H Hydraulic Tube Fittings, 304H SS Twin Ferrule Fittings Supplier in Mumbai.

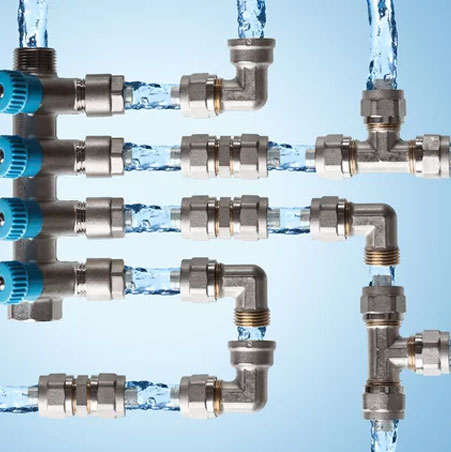

Unifit Metal Alloys is a recognised exporter and trader of SS 304H Tube Fittings, which comes in a range of common sizes and are extremely simple to set up Our quality control personnel examine this Stainless Steel UNS S30409 Union Elbow Tube Fittings in accordance with industry norms. These alloys include blow-out-proof stems, vented balls, and lever misalignment prevention as common features that add to secure handling and trouble-free operation. We provide an unrivalled variety of this alloy, which is manufactured using sophisticated equipment and novel technology in accordance with international quality regulations and standards. Our robustly and rigidly produced variety of this alloy is used in industrial piping systems for perfectly joining two lines with no danger of material leakage. Furthermore, we provide this alloy at a cheap cost to our esteemed customers.

DIN 1.4301 Ferrule Fittings, SS 304H Reducing Union, Stainless Steel 304H Union Elbow, UNS S30409 Tube Fittings, SS 304H Tube To Union, Stainless Steel 304H Female Connector, 304H Stainless Steel Single & Double Ferrule Tube Fittings, SS 304H Back FerruleManufacturer In Mumbai, India.

Stainless Steel WNR. 1.4948 Bulkhead Elbow Tube Fittings is carefully evaluated at different phases in accordance with industry standards. Our business is well-known for providing this alloy to clients, which is extensively used in the building sector. The inclusion of other elements to create alloys increases the strength of this alloy. It has characteristics such as rust resistance, low maintenance, longer useful life, light weight, ease of use, anti-crack, smooth surfaces, unrivalled quality, perfectly designed, durable, and dimensionally correct, corrosion resistance, and more. Furthermore, our customer can obtain this alloy in a variety of specs at affordable rates.

This alloy's variety is well-known in the market for providing long-lasting binding. 304H Stainless Steel Union Tee Tube Fittings are made of high-quality materials and sophisticated technologies to guarantee the safe transport of liquefied and gaseous substances in petrochemical, gas, oil, chemical, and food manufacturing units. It is also extensively used in oil and gas pipelines, plumbing, heating, the chemical industry, power plants, fabrication, and other industrial applications. It eliminates hypersensitivity and inter-granular rust issues. Furthermore, the offered alloy is carefully evaluated at various phases in accordance with the industry standards. It has anti-corrosive, durable, and robust properties, among others. This metal can be strengthened further using methods that divide alloys into two categories: non-heat treatable and heat treatable.

Get a best quote for SS TP304H Tube Fittings, We Keep Bulk Stock of Stainless Steel 304H Tube To Union at our stockyard, contact us to request a quote.

Stainless Steel 304H Tube Fittings Specifications

| Specifications | ASTM A182, A276, A479 / ASME SA182, SA276, SA479 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |