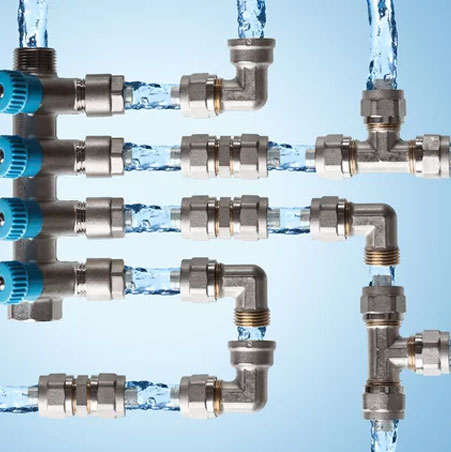

SS 304 Male Connector, Ready Stock Of SS 304 Bulkhead Union, Stainless Steel 304 Female Elbow, Manufacturer of ASTM A182 TP304 Hydraulic Tube Fittings, 304 SS Twin Ferrule Fittings Supplier in Mumbai.

Unifit Metal Alloys is a recognised exporter and manufacturer of SS 304 Tube Fittings, whichhave an exceptional and faultless performance life. Stainless Steel UNS S30400 Union Tube Fittings are well-known for their longevity and strength. It has characteristics such as optimal performance, strong construction, high efficiency, robust construction, high strength, rugged design, and more. We have several years of manufacturing experience and are proud to give this alloy, which is made of high quality galvanized steel material. It is offered in welded method finish, as well as various surface treatments such as black painting, anti-rust oil, hot galvanized, and others. It performs well in carbonizing and chloride-containing conditions. Slower rates and positive feeds will reduce this steel's propensity to work harden and glaze. Because of the greater nickel and molybdenum alloying, it functions better than other austenitic stainless steels.

Stainless Steel 304 Union Elbow, 304 Stainless Steel Single & Double Ferrule Tube Fittings, SS 304 Tube To Union, DIN 1.4301 Ferrule Fittings, Stainless Steel 304 Female Connector, UNS S30400 Tube Fittings, SS 304 Reducing Union, SS 304 Back Ferrule Manufacturer In Mumbai, India.

Stainless Steel WNR 1.4301 Reducing Union Tube Fittings is widely regarded for its excellent performance, long-lasting finish standards, and dependability. You can purchase this alloy for flawless connection and crucial uses, superb pricing, and a wide measurement variety. They have a rigid construction that protects the pipeline systems of the hydrocarbon, food processing, chemical, gas, and petrochemical sectors. Furthermore, it is tested on numerous quality criteria to ensure flawlessness before being distributed to the market. We provide this alloy, which is made from high-quality raw materials and is also produced with advanced technology to guarantee the highest quality laminations.

We are constantly involved in providing a broad range of this 304 Stainless Steel Bulkhead Union Tube Fittings, which is made using fundamental raw materials and cutting-edge technology in accordance with industry standards. It is used in low and medium pressure fluid pipelines, the hydrocarbon and natural gas industries, drilling, and construction. It has good mechanical characteristics and is nonmagnetic. It has characteristics such as long-lasting, sturdy forms, rust resistance, and more. Furthermore, our customer can obtain this alloy in a variety of specs at affordable rates. Our esteemed clients can obtain a quality-approved selection of this alloy from us, which is available in a variety of forms to meet the requirements of the customers.

Get a best quote for SS TP304 Tube Fittings, We Keep Bulk Stock of Stainless Steel 304 Tube To Union at our stockyard, contact us to request a quote.

Stainless Steel 304 Tube Fittings Specifications

| Specifications | ASTM A182, A276, A479 / ASME SA182, SA276, SA479 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |