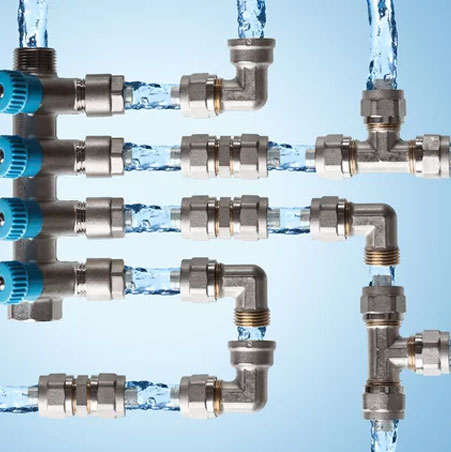

Manufacturer of ASTM A182 TP316H Hydraulic Tube Fittings, Ready Stock Of SS 316H Bulkhead Union, Stainless Steel 316H Female Elbow, 316H SS Twin Ferrule Fittings, SS 316H Male Connector Supplier in Mumbai.

Unifit Metal Alloys is a recognised supplier and manufacturer of SS 316H Tube Fittings, whichhas excellent soldering properties. Stainless Steel UNS S31609 Bulkhead Female Connector Tube Fittings outperforms other alloys in most conditions due to its high chromium and nickel concentration. For this steel, standard welding methods include MAG-Welding Solid Wire, Arc Welding (E), TIG-Welding, Laser Beam Welding, and others. While most austenitic metals keep excellent strength when subjected to high temperatures, these steels retain strength and toughness at sub-zero temperatures. It is easy to fabricate and sanities, prevents product contamination, and comes in a variety of finishes and looks. It has a high nickel content that ranges between 8 percent and 10.5 percent by weight, as well as a high chromium content that ranges between 18% and 20% by weight.

SS 316H Tube To Union, Stainless Steel 316H Union Elbow, SS 316H Reducing Union, Stainless Steel 316H Female Connector, SS 316H Back Ferrule, UNS S31609 Tube Fittings, SS 316H Ferrule Fittings, 316H Stainless Steel Single & Double Ferrule Tube Fittings Manufacturer In Mumbai, India.

Stainless Steel WNR 1.4918 Female Elbow Tube Fittings may contain much greater amounts of chromium as well as other alloying elements such as titanium, aluminum, molybdenum, nickel, copper, phosphorous, nitrogen, and selenium. Before quickly cooling, it must be heated to between 1,900 and 2,100 degrees Fahrenheit (1,038 to 1,149 degrees Celsius). It is used in cookware, cutlery, big tools, surgical devices, and huge structure construction. Because it is resistant to sensitization, it is commonly used in large gauge welded components. It is also used in oil and hydrocarbon refining equipment, base plates, aerospace structures, food preparation equipment, and a variety of other applications.

316H Stainless Steel Female Run Tee Tube Fittings is widely used in chemical processing machinery when greater corrosion protection than chromium-nickel steels is needed. Traditional hot working techniques are possible in this metal. It is a molybdenum-containing austenitic stainless steel with superior corrosion protection when compared to other metals. It's extensively used in sectors like aerospace, chemical, building, and automobile. In comparison to this steel, higher amounts of chromium, nickel, and molybdenum increase resilience to chloride pitting and general corrosion. The addition of molybdenum to steel increases its resilience to chloride pitting. It confirms improved erosion resilience in harsh environments with a wide range of substances, especially in acidic chloride environments.

Get a best quote for SS TP316H Tube Fittings, We Keep Bulk Stock of Stainless Steel 316H Tube To Union at our stockyard, contact us to request a quote.

Stainless Steel 316H Tube Fittings Specifications

| Specifications | ASTM A182, A276, A479 / ASME SA182, SA276, SA479 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |