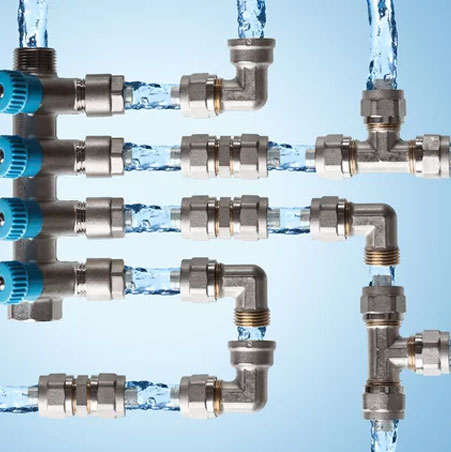

Ready Stock Of Super Duplex S32760 Bulkhead Union, Manufacturer of ASTM A182 SDSS S32760 Hydraulic Tube Fittings, Super Duplex Steel S32750 Female Elbow, Super Duplex Stainless Steel S32750 Male Connector, S32750 SDSS Twin Ferrule Fittings Supplier in Mumbai.

Unifit Metal Alloys is a supplier of Super Duplex Tube Fittings, whichis nonmagnetic in annealed and cold worked circumstances and rust resistant.

Preheating is not required for this Super Duplex Steel S32750 Bulkhead Female Connector Tube Fittings, where the inter pass temperature should not surpass 150° C and heat treating after welding is not common. Heat from 1050° C to 1150° C and water quench; this process guarantees that all carbides are in solution in this alloy.The primary features of these goods are their high chromium and medium nickel concentration, which makes them resistant to oxidation, suffixation, and other types of hot corrosion. Because of its outstanding general qualities, this steel is used in a broad range of sectors for a variety of uses.

DIN 1.4501 Ferrule Fittings, Super Duplex Steel UNS S32750 Tube Fittings, SAF 2507 Tube To Union, Super Duplex S32750 Reducing Union, Super Duplex Steel S32760 Union Elbow, S32750 Super Duplex Steel Single & Double Ferrule Tube Fittings, Super Duplex Stainless Steel S32760 Female Connector, SDSS S32760 Back Ferrule Manufacturer In Mumbai, India.

Super Duplex Steel S32760 Female Elbow Tube Fittings should be made at around 2150oF (1175oC) and no lower than 1800oF. (980 Degree C). They are given for information only and should not be interpreted as maximum or minimal numbers for specification, final design, or a specific use or application. It is essential to maintain the instrument cutting at all times and to use chip breakers where the fragments are stringy and the work will harden quickly. It is not recommended for the extreme thermal stress caused by repetitive liquid cooling. It comes in nominal diameter / schedule variations.

Super Duplex 2507 Female Run Tee Tube Fittings has also proven to be immune to aquatic environments. It is an austenitic heat resistant alloy with good oxidation resistance under slightly cyclic circumstances up to 2000 degrees F. It is one of the most commonly used types of heat resistant stainless steel in a variety of industries. It is an excellent heat resistant alloy with strong strength at temps up to 2100 degrees Fahrenheit. It is possible to supply a high grade stainless precision ground bar to your tight tolerances. It's used in things like combustion tubes, refractory anchor bolts, fire box sheets, furnace components, and other high-temperature containers. The atmospheres of commercial heat treating ovens are more seriously carburizing.

Get a best quote for SDSS S32750 Tube Fittings, We Keep Bulk Stock of Super Duplex Steel S32760 Tube To Union at our stockyard, contact us to request a quote.

Super Duplex Steel S32750/S32760 Tube Fittings Specifications

| Specifications | ASTM A182, A276, A479 / ASME SA182, SA276, SA479 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |