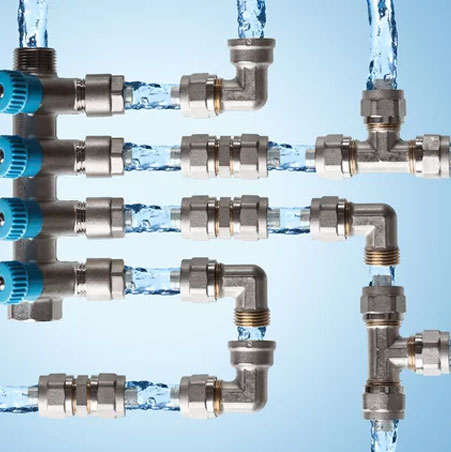

Manufacturer of ASTM B366 Nickel 200 Hydraulic Tube Fittings, Nickel Alloy 200 Male Connector, Nickel 201 Twin Ferrule Fittings, Ready Stock Of Nickel Alloy 201 Bulkhead Union, Alloy 200 Female Elbow Supplier in Mumbai.

Unifit Metal Alloys is a well-known seller and distributor of Nickel 200 / 201 Tube Fittings, whichis impervious to splitting and pitting caused by chloride stress corrosion. Nickel UNS N02200 Bulkhead Male Connector Tube Fittings are utilised in corrosive conditions and at high temperatures in a range of applications such as petrochemical andchemical processing, heat treatment equipment, the paper pulp industry, and nuclear power plants.Its chemical makeup is intended to provide extraordinary resilience to a wide range of corrosive conditions. Nickel WNR 2.4066 Male Elbow Tube Fittings is frequently used in the manufacture of paper pulp, where the nickel concentration is adequate to withstand chloride-ion stress-corrosion cracking. Shielded metal-arc welding, gas-tungsten arc welding, gas metal-arc welding, and submerged-arc welding are all used to join it.

Alloy 200 Reducing Union, Alloy 201 Single & Double Ferrule Tube Fittings, Nickel Alloy 201 Back Ferrule, DIN 2.4375 Ferrule Fittings, Nickel Alloy 201 Female Connector, UNS N02200 Tube Fittings, Nickel Alloy 200 Union Elbow, Nickel 200 Tube To Union Manufacturer In Mumbai, India.

Stress relief or annealing for Ni-200 Male Run Tee Tube Fittings should be considered based on the overall amount of strain caused by manufacturing while keeping the intended service of the material in mind. It is used in ethylene furnace quench furnaces, hydrocarbon splitting, valves, connections, and other components that are subjected to corrosive assault between 1100 and 1800 degrees Fahrenheit. Nickel UNS N02201Male Branch Tee Tube Fittings was created to be a saltwater proof material, but it has since been shown to be immune to a wide variety of extremely corrosive conditions. Its stress relief is done between 1000 and 1600 degrees Fahrenheit and should be at temperature of material or a minimum of 112 hours at 1600 degrees Fahrenheit, whichever is higher.

Nickel WNR 2.4068 Positionable Male Run Tee Tube Fittings is used in power facilities for super-heater and re-heater pipes.The nickel in this steel, along with the molybdenum and copper, provides excellent resilience to reducing conditions such as sulphuric and phosphoric acids. Ni-201 Female Connector Tube Fittings have good resilience to chloride stress-corrosion cracking and can be heat treated by annealing; however, heat treatment does not harden them. And since excessive grain development can have a detrimental impact on mechanical qualities in this steel, the annealing temperature and duration at temperature must be carefully chosen.

Get a best quote for Alloy 200 Tube Fittings, We Keep Bulk Stock of Nickel Alloy 201 Tube To Union at our stockyard, contact us to request a quote.

Nickel Alloy 200/201 Tube Fittings Specifications

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 4000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |