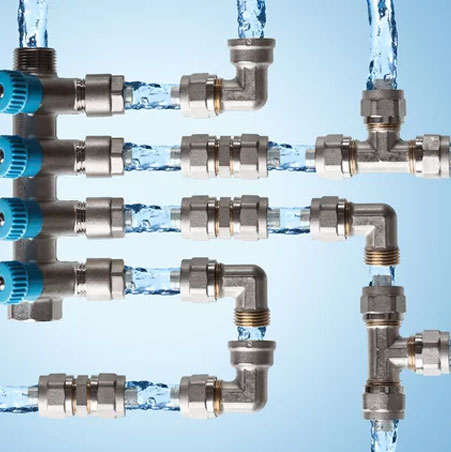

Manufacturer of ASTM B366 Inconel® Alloy 600 Hydraulic Tube Fittings, Ready Stock Of Inconel 600 Bulkhead Union, Inconel Alloy 600 Male Connector, Inconel 600 Female Elbow, Nickel Alloy 600 Twin Ferrule Fittings Supplier in Mumbai.

Unifit Metal Alloys is a supplier of Inconel Alloy 600 Tube Fittings, which frequently has lower minimum strengths than conventional steels. Inconel UNS N06600 Reducing Union Tee Tube Fittings is absolutely adequate for many other purposes. When exposed to tensile strains over roughly 50 degrees Celsius in hot chloride conditions, it is prone to pitting and crevice corrosion, as well as stress corrosion cracking. It is an austenitic stainless steel with a high work-hardening rate that can become somewhat magnetic when cold worked. They are well-known for their durability, exquisite finishing, high tensile strength, and corrosion resistance, and they meet the demands of the construction and engineering sectors. It is non-magnetic when annealed, but can become mildly magnetic after cold treatment or welding.

Inconel Alloy 600 Tube To Union, Inconel 600 Back Ferrule, Alloy 600 Reducing Union, DIN 2.4816 Ferrule Fittings, UNS N06600 Tube Fittings, Incoloy 600 Female Connector, Inconel 600 Union Elbow, Alloy 600 Single & Double Ferrule Tube Fittings Manufacturer In Mumbai, India.

Inconel WNR 2.4816 Union Cross Tube Fittings is also utilised in environmental scrubbers, feed-water tubes, duct works, sewage water filters, ozone generators, heat exchanger tubes, and other applications. At higher temperatures, it has greater strength and creep resistance. It is used in the chemical process sector to hold hot concentrated acids, ammonia, and sulphur dioxide, as well as in the food processing business to contain hot acetic and citric acid. Cold working increases the steel's strength and hardness, and it offers good corrosion resistance when exposed to a variety of corrosive conditions and media.

Nickel Alloy 600 Male Connector Tube Fittings has a high oxidation resistance in intermittent service up to 870° C and in continuous operation up to 925° C. This alloy requires special care to minimise weld "hot cracking" by ensuring the production of ferrite in the weld deposit. This product's regulated analysis allows it to keep adequate ductility in situations ranging from soft with hard to be roll or brake formed into aviation, architectural, and notably train car structural components. Pressure vessels, heat exchangers, tanks, piping systems, valves, and pumps are further examples of its applications in chemical and petrochemical processing. Even in martens tic stainless steels, it possesses better hot strength than carbon alloys. It is also titanium-stabilized against the production of chromium carbide.

Get a best quote for Alloy 600 Tube Fittings, We Keep Bulk Stock of Inconel 600 Tube To Union at our stockyard, contact us to request a quote.

Inconel 600 Tube Fittings Specifications

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |