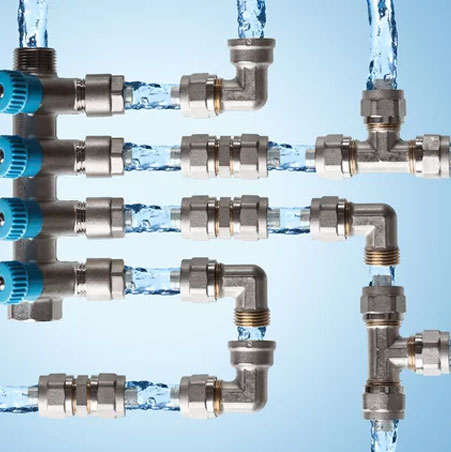

Monel Alloy 400 Male Connector, Manufacturer of ASTM B366 Monel® Alloy 400 Hydraulic Tube Fittings, Ready Stock Of Monel K500 Bulkhead Union, Nickel Alloy K500 Twin Ferrule Fittings, Monel 400 Female Elbow Supplier in Mumbai.

Unifit Metal Alloys is a well-known stockist and seller of Monel 400 / K500 Tube Fittings, which are highly resistant to rust. Monel UNS N04400 Union Elbow Tube Fittings has excellent mechanical properties in both room and higher temps up to about 1000 degrees F, where equipment design is typically based on tensile characteristics.

As previously stated, cold labour can significantly improve it. This product's chromium concentration imparts resilience to a variety of oxidising substances, including nitric acid, nitrates, and oxidising salts. Monel WNR 2.4360 Bulkhead Elbow Tube Fittings has a variety of applications, including furnace muffles, electrical components, and heat treating machinery, steam generator tubing, and heat exchangers. This device was designed to withstand a wide range of corrosive conditions, both oxidising and reducing. This is a high-performance nickel-iron-chromium metal with molybdenum, copper, and titanium addition.

Alloy K500 Single & Double Ferrule Tube Fittings, Monel K500 Female Connector, Alloy 400 Reducing Union, Monel 400 Union Elbow, Monel K500 Back Ferrule, UNS N04400 Tube Fittings, DIN 2.4375 Ferrule Fittings, Monel Alloy 400 Tube To Union Manufacturer In Mumbai, India.

When compared to traditional austenitic alloys, this steel's nickel composition makes Alloy 400 Union Tee Tube Fittings immune to chloride stress-corrosion cracking and, when coupled with molybdenum and copper, offers significantly enhanced corrosion resistance in reducing environments. The nickel in this steel, combined with the molybdenum and copper, provides excellent resilience to reducing conditions such as sulphuric and phosphoric acids. Monel UNS N05500 Reducing Union Tee Tube Fittings is used in a variety of sectors and uses due to its excellent corrosion protection properties. It is a nickel and chromium alloy with good tensile strength, resilience to oxidation, and carburization characteristics.

Monel WNR 2.4375 Union Cross Tube Fittings is used in a variety of applications including chemical processing, nuclear fuel reprocessing, acid production, pickling equipment, and others. Its notable feature is its corrosion resistance, with approval for pressure-vessel applications at wall temps up to 800 degrees Fahrenheit. This steel's molybdenum content makes it resistant to pitting and fissure rust. Alloy K500 Male Connector Tube Fittings has a high impact strength at room temperature and maintains its strength at cryogenic temps, where the alloy's compressive yield strength is comparable to its tensile yield strength. Its molybdenum and chromium composition providesconfrontation to chloride pitting in addition to resilience to anassortment of oxidising atmospheres.

Get a best quote for Alloy 400 Tube Fittings, We Keep Bulk Stock of Monel K500 Tube To Union at our stockyard, contact us to request a quote.

Monel 400/K500 Tube Fittings Specifications

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 4000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |