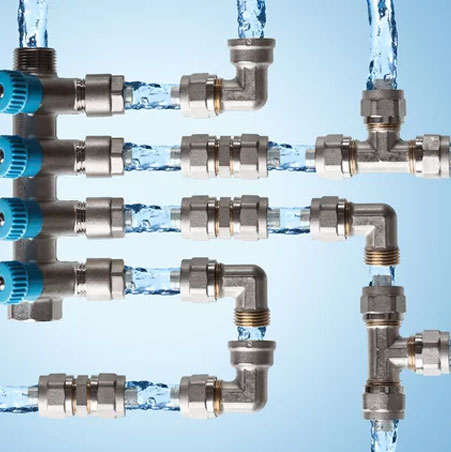

Ready Stock Of Incoloy 825 Bulkhead Union, Incoloy 825 Female Elbow, Manufacturer of ASTM B366 Incoloy® Alloy 825 Hydraulic Tube Fittings, Incoloy Alloy 825 Male Connector, Nickel Alloy 825 Twin Ferrule Fittings Supplier in Mumbai.

Unifit Metal Alloys is a recognised supplier and exporter of Incoloy Alloy 825 Tube Fittings, which is more ductile and resistant to stress fracture. When selecting a filler metal, such as this Incoloy UNS N08825 Union Elbow Tube Fittings, corrosion stress must also be considered. It is suitable for situations where carbide precipitation occurs in non-stabilized grades. They are also suggested for components to be used at temperatures ranging from 427° C to 816° C), since they have strong resistance to intergranular corrosion. It is resistant to oxidation up to 1500 degrees Fahrenheit and has better creep and stress rupture qualities. It enhances the alloy's increased temperature characteristics. It will preserve its strength and toughness at sub-zero temperatures while preserving good strength and corrosion resistance when exposed to hot temperatures.

Alloy 825 Reducing Union, Incoloy 825 Female Connector, Incoloy 825 Back Ferrule, Incoloy Alloy 825 Tube To Union, UNS N08825 Tube Fittings, Alloy 825 Single & Double Ferrule Tube Fittings, DIN 2.4858 Ferrule Fittings, Incoloy 825 Union Elbow Manufacturer In Mumbai, India.

Incoloy WNR 2.4858 Bulkhead Elbow Tube Fittings is generally employed in applications that need constant and intermittent service temperatures in the carbide precipitation array. Titanium content is used in this steel to prevent grain boundary Chromium Carbide precipitation and to make it more resistant to intergranular corrosion. It is a fantastic choice for a wide range of applications, including oil refinery equipment and vehicle exhaust systems. Unfortunately, the incorporation of titanium limits the working applicability of this steel. Due to the cast structure of the weld metal, the use of an advanced alloyed filler metal in this steel may be required.

Nickel Alloy 825 Union Tee Tube Fittings may be found in oil refinery equipment, jet aircraft components, diesel and heavy duty car exhaust systems, and soaring temperature chemical process equipment. The titanium ingredient in this alloy makes it more resistant to the development of chromium carbide. It also has good low temperature toughness and is non-magnetic when annealed. It is still used for long-term service at temperatures ranging from 427° C to 816° C. It is appropriate for applications where this steel will get sensitised or when hot strength is insufficient. It is used to give the best possible resistance to inter-granular erosion in the heat affected zone (HAZ) and polyphonic acid stress corrosion cracking.

Get a best quote for Alloy 825 Tube Fittings, We Keep Bulk Stock of Incoloy 825 Tube To Union at our stockyard, contact us to request a quote.

Incoloy 825 Tube Fittings Specifications

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 8250 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |