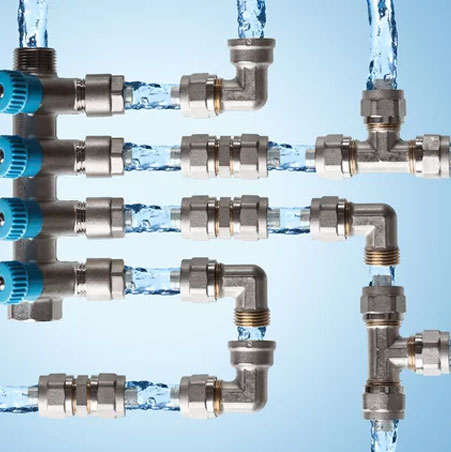

Hastelloy Alloy C276 Male Connector, Manufacturer of ASTM B366 Hastelloy® Alloy C276 Hydraulic Tube Fittings, Ready Stock Of Hastelloy C276 Bulkhead Union, Nickel Alloy C276 Twin Ferrule Fittings, Hastelloy C276 Female Elbow Supplier in Mumbai.

Unifit Metal Alloys is a supplier and exporter of Hastelloy Alloy C276 Tube Fittings, which has better corrosion resistance than any other steel. When annealed, Hastelloy WNR 2.4819 Union Elbow Tube Fittings are largely nonmagnetic and become faintly magnetic when cold worked. Because steels like this one have been optimised at high temperatures, their resistance to aqueous erosion has been restricted.It is not recommended for severe thermal stress caused by frequent liquid quenching. Because of its improved formability and weld ability, it is the low carbon variant and is used for simplicity of construction. It's perfect for high-temperature applications including heat treatment and chemical processing machinery. It is a superb choice for a wide range of applications, including furnace components and burner tips.

DIN 2.4819 Ferrule Fittings, Hastelloy C276 Union Elbow, UNS N10276 Tube Fittings, Alloy C276 Single & Double Ferrule Tube Fittings, Hastelloy Alloy C276 Tube To Union, Hastelloy C276 Back Ferrule, Alloy C276 Reducing Union, Hastelloy C276 Female Connector Manufacturer In Mumbai, India.

Hastelloy UNS N10276 Bulkhead Elbow Tube Fittings is often utilised for high-temperature applications due to its high nickel and chromium content, which provides strongerosion resistance, inordinatecorrosion resistance, and excellentpotency at temperatures up to 2100 degrees Fahrenheit. It is frequently utilised at cryogenic temperatures because to its high toughness and low magnetic permeability. Because this steel is extremely robust, its resistance to cold temperatures is beneficial in cryogenic conditions.It is frequently used in power reactors, thermal treatment, and food processing. It is often used in chemical plants and equipment, such as fasteners for high-temperature operations, muffles, heat exchangers, and components for high-temperature sulphur-bearing environments.

Nickel Alloy C276 Union Tee Tube Fittings possesses strong oxidation resistance, high-temperature corrosion resistance, and mechanical strength at high temperatures. Forming operations in this steel should be completed at room temperature whenever feasible when employing high speed steel tools. It is an austenitic heat resistant alloy with outstanding oxidation resistance in gently cyclic circumstances.Customers all around the world rely on our machining and precise grinding business unit for this steel for metal car steering and powder metal components.It is utilised in pressure vessels, piping systems, slurry tanks, tanks, stack liners, and valves, among other things. Any cold working processes on this alloy will improve its strength and hardness while also leaving it mildly magnetic.

Get a best quote for Alloy C276 Tube Fittings, We Keep Bulk Stock of Hastelloy C276 Tube To Union at our stockyard, contact us to request a quote.

Hastelloy C276 Tube Fittings Specifications

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |