Duplex Stainless Steel S31803 Male Connector, Ready Stock Of Duplex S32205 Bulkhead Union, Manufacturer of ASTM A182 DSS S32205 Hydraulic Tube Fittings, Duplex Steel S31803 Female Elbow, S31803 DSS Twin Ferrule Fittings Supplier in Mumbai.

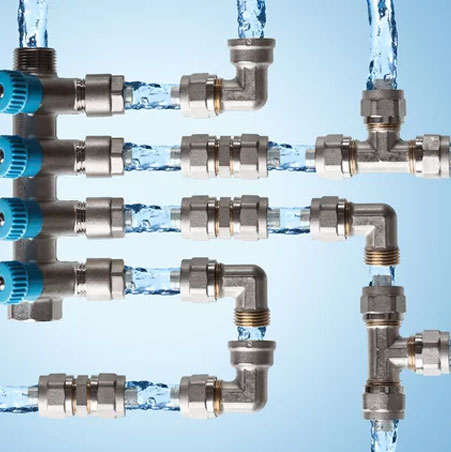

Unifit Metal Alloys is a supplier of Duplex Steel Tube Fittings, whichare chromium-containing general-purpose martensitic steels with high corrosion resistance.

When strength, hardness, and/or wear resistance must be coupled with corrosion resistance, this Duplex Steel S31803 Union Tube Fittings is employed. This steel has excellent strength and hardness, as well as exceptional corrosion resistance. The maximum strength, wear resistance, and corrosion resistance are obtained by oil quenching these goods at temperatures ranging from 982°C - 1066°C.We offer fair pricing and high-quality products like this steel tailored to your specifications. It has exceptional high strength and corrosion protection, but due to its limited carbon content, it can create stronger welds.

S31803 Duplex Steel Single & Double Ferrule Tube Fittings, DSS S32205 Back Ferrule, Duplex Steel S32205 Union Elbow, Duplex S31803 Reducing Union, DIN 1.4462 Ferrule Fittings, SAF 2205 Tube To Union, Duplex Stainless Steel S32205 Female Connector, Duplex Steel UNS S31803 Tube Fittings Manufacturer In Mumbai, India.

Duplex Steel S32205 Reducing Union Tube Fittings have high scaling resistance in continuous service up to 650° C. They are resistant to moderate organic and mineral acids at low concentrations. These are chromium-containing general-purpose martensitic steels with high corrosion resistance.It can withstand temperatures of up to 1200 degrees Fahrenheit (650 degrees Celsius) and is easily hot worked by forging and jarring. With various heat treatments, it can produce a broad variety of characteristics, including ultimate tensile strengths. For optimum through hardness, this product can be air chilled and bigger portions oil quenched. Nuts, bushings, fasteners, gas turbine parts, mine equipment, pump parts, petrochemical equipment, steam turbine parts, studs, valve parts, and so on are typical uses.

When properly cleaned after use, the exposure of this Duplex Alloy 2205 Bulkhead Union Tube Fittings to daily activities is usually satisfactory. Heat to 1500 - 1650 degrees Fahrenheit, then gently reduce to 1100 degrees Fahrenheit, after which air cooling is permitted. The appropriate hot work range for this steel is 2000 degrees Fahrenheit to 2200 degrees Fahrenheit (1093 degrees Celsius to 1204 degrees Celsius), but do not work this substance below 1650 degrees Fahrenheit (899 Degree C).This product's rust protection can be improved further through a number of procedures such as hardening, tempering, and polishing.It has excellent corrosion protection, ductility, and is well adapted for extremely stressed components.

Get a best quote for DSS S31803 Tube Fittings, We Keep Bulk Stock of Duplex Steel S32205 Tube To Union at our stockyard, contact us to request a quote.

Duplex Steel S31803/S32205 Tube Fittings Specifications

| Specifications | ASTM A182, A276, A479 / ASME SA182, SA276, SA479 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application | |

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |